The perfect cocoa

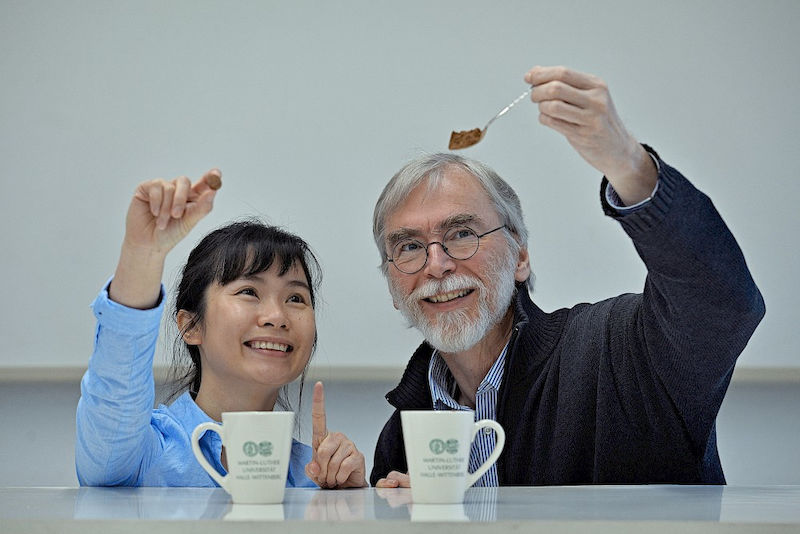

The perfect cocoa obviously has to taste good. But that’s far from being enough. Take, for example, those lumps that float on the surface of your beverage. Those lumps that remain even after vigorous stirring. Mashing them with a spoon helps – but not always. PhD student ThiNhat Phuong Nguyen demonstrates that this doesn’t always have to happen. Her means to an end: fast dissolving tablets. Take a cup, fill it with milk, toss in a tablet, stir, and you’re done.

No lumps. No cocoa stuck to your spoon. No powder that can spill and mess up your kitchen. Just the right serving size. It’s a little bit of food magic. Witty and innovative, but not really a revolution. Yet, there is something to be said for the idea behind it. If it’s possible to develop a tablet that can dissolve a difficult-to-dissolve active ingredient faster than usual, it would put an end to many pharmaceutical problems. “Many of the active ingredients that have been developed dissolve very slowly,” says Nguyen’s doctoral supervisor, Prof. Dr. Joachim Ulrich.

“However it is immensely important to get the speed at which they dissolve right.” If the active ingredient dissolves too quickly, this results in local poisoning. If the process lasts too long, the active ingredient remains below its critical value and the effects are zero. What’s missing is a technique for manufacturing tablets that dissolve quickly and controllably. Says Ulrich, “The surface is the only starting point we have.” Lots of surface means lots of contact with the solvent, which means the tablet will disappear quickly. Ulrich has gathered ideas from ceramics about how something like this could work.

Luft hilft der Kakaotablettte beim Auflösen

He has helped develop a technique to make featherweight ceramic products using tiny cavities. Why not also apply this technique to tablets? Having a lot of air inside means having a lot of space that can be filled with the solvent. This is where Nguyen comes in. It was her task to develop this technique – using food rather than a drug. “This was simply due to the fact that testing new drug formats can take around seven years. But no one has that much time to write a dissertation,” Ulrich explains. “The food industry is much less complicated, it’s quicker, and has an affinity for innovation.” “The biggest problem was finding a food that the application made sense for,” reveals the young process engineer.

“And then there’s the binder. When we manufacture tablets, they are held together by pressure and by something that acts like an adhesive. Naturally, this mustn’t change the taste and has to be approved for use in food. And it has to be correctly dosed.” Ultimately a decision was made to use cocoa as the foodstuff and sugar as the binder.

The manufacturing process is simple in theory, yet relatively complicated to implement. Water is added to the cocoa and then frozen. Nguyen can control the size and shape of the developing ice crystals. The cocoa is pressed into a mould and then the ice is vaporized. The crystals are replaced by air, in other words space that contributes to speeding up the dissolving process. The result is a solid tablet made up of around fifty percent cocoa and fifty percent air.

The advantage of this approach is that only low temperature and low pressure are required by the production process. This protects the active ingredient from becoming damaged. “However, we are not so presumptuous as to think that our method is the universal medical solution,” says Ulrich. Nonetheless, it is a universal solution when it comes to ensuring that your cocoa doesn’t clump. “Now all we have to do is find a supplier who is won over by our concept,” says the doctoral supervisor. He seems convinced that this will happen.

"Ich will die Besten"

The university’s engineering science courses were stopped around ten years ago however, the 63-year-old has continued to hold lectures in other courses of study and to supervise PhD students, other students wanting to write their degree theses, post-docs and guest researchers. Around half of his doctoral candidates are women, half are from abroad, and only half have studied his field of process engineering. “When you are good at a related subject, you will quickly learn the knowledge that is needed. I can work with that. I want the best – full stop.” The bulk of his research work is already interdisciplinary.

His team consists of food chemists, pharmacists and engineers, just to name a few. Nguyen is one of his best. The Vietnamese student initially studied process engineering in Vietnam and Korea. She then travelled to Germany to do her doctorate. She came into contact with the university through a summer school that Ulrich organised in Korea.

It took only 30 minutes for the ambitious scientist to receive a response to her application to Martin Luther University. The mentoring is good and there is a high level of education and things on offer. Halle is forcing her to speak German, which is helpful because Nguyen would like to continue to conduct research in Germany. It remains to be seen whether this will pan out, however her chances are nothing short of good.

Contact: Prof. Dr. Joachim Ulrich

Thermic process engineering

Phone: 0345 5528400

Send email