The researcher who flies through nanoworlds

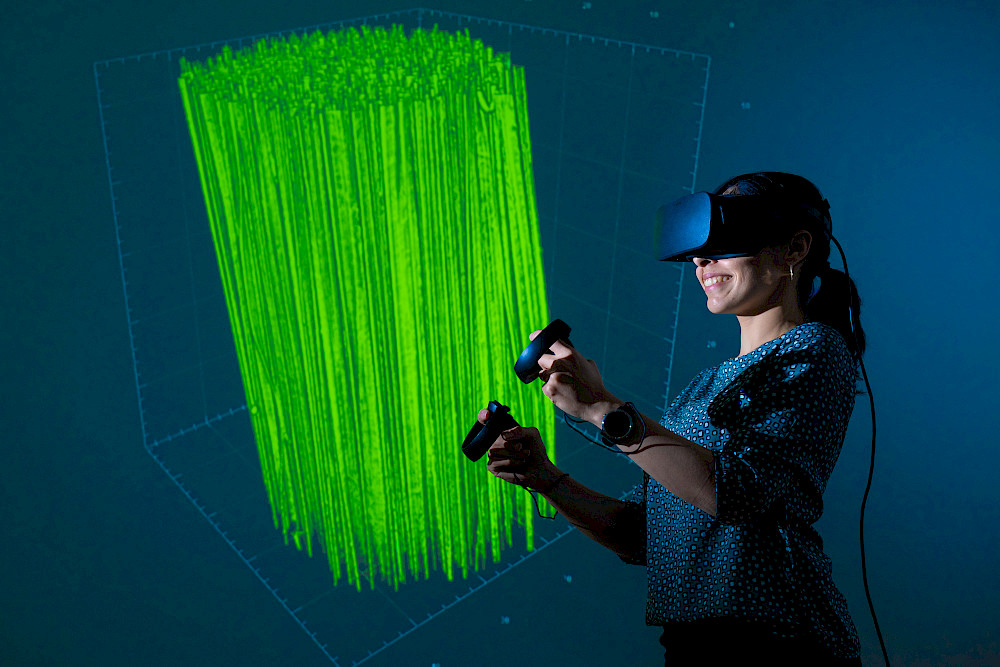

With a virtual reality headset on and controllers in hand, she looks more like she’s playing a video game. But for Dr Juliana Martins de Souza e Silva, it is all about research. She has come to the University of Halle to do research using the ZEISS Xradia 810 Ultra X-ray microscope. Using the VR headset, she moves - not in virtual fantasy worlds - but in places that are normally hidden from view. She can use the headset to “fly” through tiny samples of materials whose images were taken with a microscope. It’s a technique that has already netted the 41-year-old several international collaborations, and publications in top-tier journals.

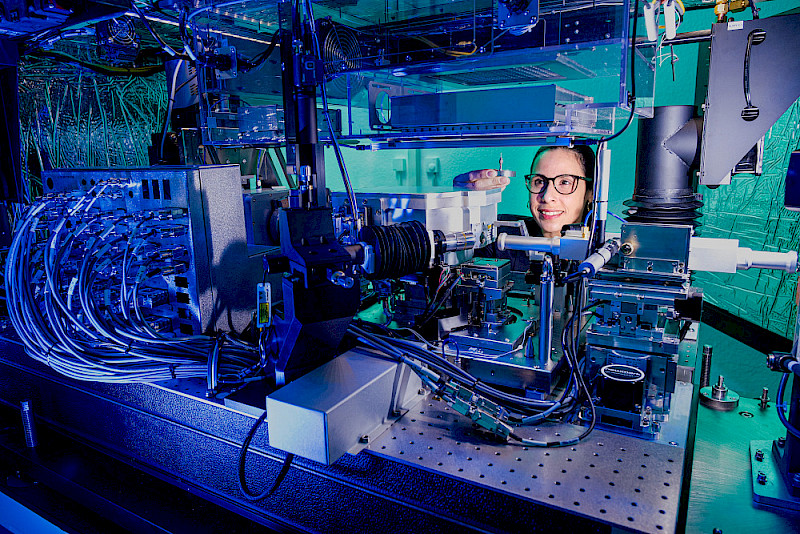

The device was purchased by the university in late 2017 with funds from a large-scale equipment initiative of the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation). It is intended to accelerate the development of new materials and advance the university’s core research area “Nanostructured Materials”. It is the 49th microscope of its kind in the world - the third one in Germany having been recently installed in Hamburg, Martins says. But it is not enough to just have such a microscope. “It takes a few months to learn the best way to prepare samples and set up the best configurations for the experiments,” the scientist explains. In the beginning, she says, she put all sorts of things under the microscope to learn how to use the instrument and adjust the settings. An insect leg, for example, or hair or pollen. “It's amazing what you can see: the scaly structure of a leg or hair, like on a fish, or to discover how many structures pollen can have.”

Martins is a chemist by trade. After earning her doctorate in Italy, she worked for several years in her native Brazil developing new materials, such as nanoparticles that can be used to fight viruses. In order to study the structure of the nanoparticles and their interaction with the virus in more detail, she went to the Technical University of Munich (TUM) for initially one year. “I wanted to study the structures using synchrotron radiation. But there is only one synchrotron in all of Brazil, whereas there are many in Europe,” she says. She simultaneously worked at TUM on a chemical method to stain the internal organs of animals in order to view them at a high level of detail using an X-ray microscope. After finishing her project and returning to Brazil, she was offered the opportunity to continue her research in Munich. From then on, she worked a lot there with another Zeiss microscope before hearing about the job offer at the University of Halle. The rare technology and the fact that she could also do her habilitation at MLU convinced her to leave Munich for Halle.

A look inside the sample

The special thing about the university’s state-of-the-art Zeiss X-ray microscope is that it does three things at once, Martins says. It X-rays the sample using typical X-ray technology, but it can also use what’s called the phase contrast technique to create a high-resolution 3D image. “Basically, it works like computed tomography in a hospital, but for extremely small things,” she says. Therefore, the technique is also referred to as nano-CT. The sample spins on its axis and the microscope sends X-rays through it. The images are later mathematically processed on a computer to form an overall picture. According to the manufacturer, the device achieves a resolution of up to 50 nanometres; in practice, structures the size of about 100 nanometres can be seen well, says Martins. By comparison, a human hair is about 70,000 nanometres thick. One advantage of X-ray technology over electron microscopy is that the sample can usually be completely “X-rayed” without destroying it. The so-called phase contrast technique exploits the fact that X-rays partially shift when passing through matter. This makes it possible, for example, to identify carbon structures, which is not possible using conventional X-ray microscopy. Combining the methods produces a 3D image which allows the sample to be viewed, not only from all angles, but from the inside as well.

This is of particular interest to the field of materials science. When a new material is produced, developers are often faced with a problem: They can use experiments to test how stable the material is and to find out what it is made of. But they can often only conjecture about how it is structured at the nanoscale. This was something faced by a research group at the University of Bayreuth. The group had developed tough, light-weight polymer fibres that had a high tensile strength and mechanical properties similar to spider silk. But the researchers were unable to conclusively prove why that was because they could only look at the outside of the fibres or at a cross-section of them. “I happened to be in Bayreuth at the time for a meeting and they spontaneously gave me a sample,” Martins says. She quickly created a 3D image and made the additional calculations needed. “I was able to show that the individual fibrils, the subunits of a fibre, were all precisely arranged in a longitudinal direction,” Martins says. In addition, the connections between the fibrils became visible. Thanks to the work done in Halle, the researchers in Bayreuth were able to publish their findings in the renowned journal “Science”. A long-term cooperation also grew out of the project.

International cooperation

A similar project followed just a short time later. This time she was approached at a conference, Martins recounts. A team from the University of California in the U.S. had developed a new, ultra-hard material almost as hard as theoretically possible for this class of material. “It is stronger than a diamond.” Again, Martins helped prove the assumed arrangement of the structure. “The challenging thing for X-ray microscopy was that the material was made of carbon,” Martins explains. Thanks to the phase contrast technique, however, she was able to easily peek inside the material. This resulted in a publication in “Nature Communications”.

Most of the time, however, Martins works with research groups at the University of Halle and the Fraunhofer Gesellschaft. The device is located in a room with a requisite vibration-free floor at the Fraunhofer Institute for Microstructure of Materials and Systems (IMWS) on the Weinberg campus. Martins supports researchers from the pharmaceutical sciences, for example, who are developing new medical materials, and teams of biologists who want to take a closer look at individual insect organs. In one project, for example, she studied thrips, tiny black insects that like to sit on bare skin in humid weather and are controlled as pests in agriculture. They fit snugly into the microscope’s holding device. The biologists wanted to take a closer look at the tiny animals’ reproductive organs. In a separate project, Martins has been studying the porosity of materials, particularly glass, that could be used as catalysts or in artificial bone. “It’s about aligning expectations with what we see under the microscope,” Martins explains. Thanks to the results of the microscopic examination, predictions can be improved. And this can be done within a short period of time, because sample preparation is typically not complicated. The material sample can be relatively large in relation to the ensuing resolution - it is often still visible to the naked eye. Using a so-called micromanipulator, it is first placed on a tiny holder and then, with the help of tweezers it is stuck onto the tip of a needle in the device. An optical microscope built into the X-ray microscope helps to locate the sample under the microscope.

Martins has no regrets about coming to Halle for the new X-ray microscope; on the contrary. “I love this microscope,” she says, laughing. The fact that it has already prompted some high-profile publications, she says, strengthens her hand in negotiations and, of course, is not bad for her career. Martins hopes to complete her postdoctoral work this year, but it will take a little longer before she can defend her thesis. In any case, she intends to stay at the university and continue her work with the microscope for a while longer.

Dr Juliana Martins de Souza e Silva

Institute of Physics

Telephone +49 345 55-28517

Mail: juliana.martins@physik.uni-halle.de